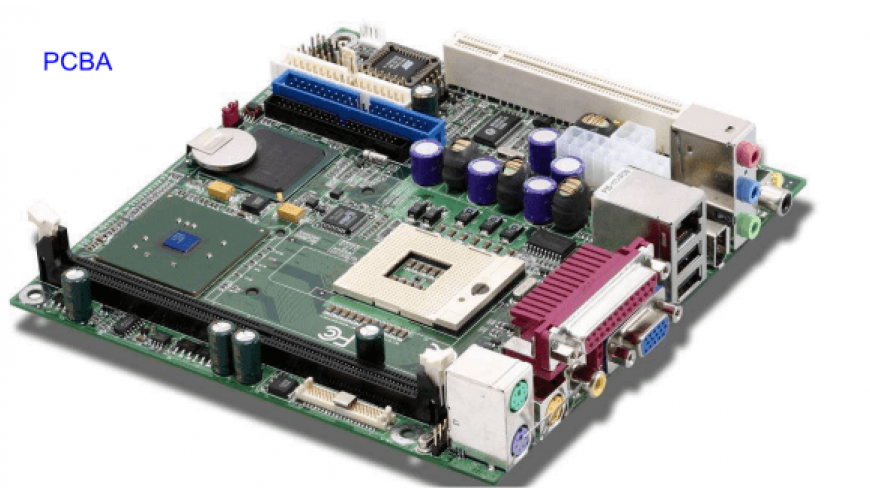

Application of rigid PCB

The compact measurement, immunity to motion, and simple maintenance helps make rigid PCBs a super item for your selection of purposes. These are particularly beneficial in industries exactly where parts should be set, and wish to cope with software tension, and elevated temperatures.Supplied beneath are some of the purposes of rigid PCBs.

Heisener offers flexible PCB assembly service. Our range of services include Quick Turn PCB, rigid flex pcb, and more PCB Customized Services. Submit a RFQ now.

Health-related: When adaptable circuits tend to be more well known in this particular sector, rigid PCBs also have a place in health care purposes. They are mostly utilized for the large sized, non-portable tools. Samples of these include things like tomography products, Electromyography (EMG) equipment, and Magnetic Resonance Imaging (MRI) methods.

Aerospace: The aerospace sector is made up of difficult, superior temperature environments. Rigid PCBs can can be found in useful in this article, because they might be built with copper and aluminum substrates, and substantial temperature laminates. Examples of aerospace programs include things like Auxiliary Energy Models (ApUs), plane cockpit instrumentation, power converters, temperature sensors, and regulate tower instrumentation techniques.

Automotive: Rigid PCBs may be located in medium to huge sized automobiles. Like aerospace purposes, the PCBs may be manufactured with higher copper and aluminum substrates. High temperature laminates is usually additional for cover in opposition to the motor heat and environmental contaminants. Automotive PCBs might also be created out of plated copper for improved sturdiness. Rigid PCBs may be used in apps these kinds of as AC/DC electric power converters, Electronic Laptop or computer Units (ECUs), transmission sensors, and electric power distribution junction packing containers.

These are definitely just a few samples of the industries and purposes during which rigid PCBs can be used. With the use of improved products and elements, the chances with the utilization of rigid PCBs is often improved. For this reason, it truly is crucial the PCB producer understands the applying prerequisite comprehensively. Like a customer, you must provide the many details the manufacturer will need to style a PCB. The combination of detailed layouts, industrial quality factors, and proficient assembly processes, may help produce a PCB that may meet up with your needs.

related articles:

preparing prior to PCB assembly

preparation ahead of PCB assembly

Area Mount Engineering (SMT) Assembly process

Surface area Mount Technological innovation (SMT) Assembly System

Komentarze